Forget the silent glide for a moment. Remember the feeling of twisting the throttle on a powerful motorcycle—the immediate surge, the connection to the road, the focus on the ride ahead. The promise of electric motorcycles is to deliver that pure sensation, amplified, without the fumes and the roar. Yet, for engineers and product managers bringing these machines to life, this promise hinges on a complex central question: what powers it?

As a lithium battery supplier embedded in this revolution, we see the conversation often stuck on a single dimension: energy density. But the battery isn’t just a “gas tank.” It’s the heart, the lungs, and a key part of the nervous system of the vehicle. Choosing it requires thinking like a motorcycle builder, not just a procurement officer.

The Current State: A Calculated Trade-Off

Today, most performance-oriented electric motorcycles run on high-nickel NCM or NCA lithium-ion batteries, predominantly in the robust 21700 cylindrical cell format. The logic is clear: maximize range and power in a lightweight package. LFP chemistry is gaining a strong foothold, especially where safety and lifetime cost are paramount.

However, this choice is a gateway to a series of fundamental engineering challenges—the true pain points that keep development teams awake at night:

- The Safety Balancing Act: High energy density has traditionally danced with higher thermal reactivity. The fear of thermal runaway isn’t just a spec sheet footnote; it dictates millions of dollars in investment into complex Battery Management Systems (BMS) and cooling architecture.

- The “Empty Tank” Anxiety: Despite advancements, range anxiety remains the ghost in the machine. It’s not just about total watt-hours, but how weight, aerodynamics, and rider behavior deplete them. The battery pack, often 30-40% of the bike’s cost, becomes a limiting factor in design.

- The Charging Lag: While EVs move towards 15-minute fast charges, most electric motorcycles still face hours to refill. Developing a fast-charging network for bikes is an infrastructural mountain yet to be climbed.

- The Cost Conundrum: Pushing the boundaries of performance makes batteries the most expensive single component, creating a tension between exhilarating specs and an attainable price tag.

The Future Is Integration, Not Just Chemistry

The next leap won’t come from a marginally better cathode chemistry alone. It will come from rethinking the battery’s role within the motorcycle’s ecosystem. We see three intertwined paths forward:

1. The Structural Revolution (From “Pack” to “Chassis”)

The future is not a battery dropped into a frame. It’s a battery as the frame. Technologies like Cell-to-Pack (CTP) and the more radical Cell-to-Chassis (CTC) are about to transform motorcycle design. By removing redundant modules and structures, we integrate cells directly into the bike’s core. This isn’t just about saving space; it’s about creating a lighter, stiffer, more dynamic chassis where every component serves multiple purposes. The battery stops being an added part and becomes a foundational element of the vehicle’s identity.

2. The Chemistry Horizon (Safety First, Performance Followed)

The quest for a “perfect” cell continues, but the goalposts are moving.

- Solid-State Batteries: This is the true game-changer. By replacing flammable liquid electrolytes with a solid, we address the core safety nightmare, potentially unlocking even higher energy densities. The road to mass production is long, but it represents the ultimate direction.

- The LFP Renaissance & Sodium-Ion’s Promise: LFP is shedding its “low-performance” tag. Through cell engineering and system integration, its superb safety and lifespan make it a compelling choice for a wider segment. On the horizon, Sodium-ion (Na-Ion) batteries whisper a promise of decoupling from volatile lithium markets, offering a cost-effective, safe, and cold-weather-resilient alternative for urban mobility solutions.

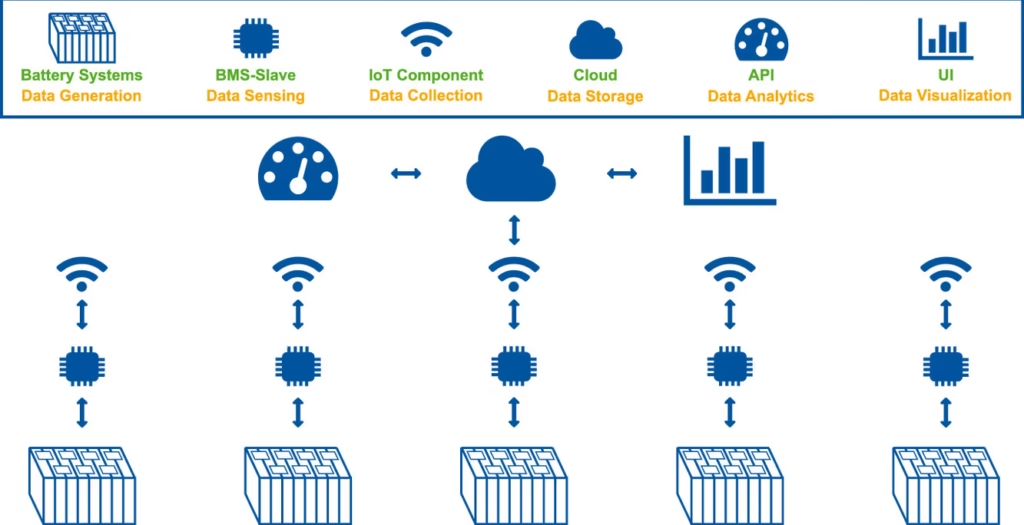

3. The Intelligence Layer (The Smart Heart)

A battery that simply stores energy is obsolete. The next-generation BMS is an onboard AI co-pilot. It won’t just prevent failure; it will predict it. It will understand rider patterns, optimize charge cycles for battery longevity, communicate with charging grids, and even enable vehicle-to-load (V2L) capabilities—turning the motorcycle into a portable power station. This intelligence transforms the battery from a consumable into a connected, evolving asset.

A Message to Fellow Builders: Collaborate Deeper, Earlier

This evolving landscape demands a new kind of partnership between battery supplier and motorcycle creator. The old model of picking a cell from a catalog after the design is frozen is a path to compromise.

The greatest innovations will happen when battery engineers and motorcycle designers share a whiteboard from day one. When the question isn’t “which battery fits our design?” but “how can we co-design the motorcycle and its heart as one inseparable, optimal system?”

At Giantpower, we believe our role is to provide more than just premium cells. It’s to bring deep technical collaboration to that whiteboard—to help navigate the trade-offs between energy density and thermal safety, to model the real-world impact of a structural pack, and to build the intelligent BMS that brings it all to life.

The electric motorcycle isn’t just a vehicle; it’s a blank canvas for a new kind of performance. And its heart, the battery, is the most important brushstroke. Let’s paint the future together.

Let’s start a conversation. What’s the most critical battery challenge in your current electric motorcycle project?

中.jpeg)